Pollutants released in vehicle emissions primarily include HC, NOx, CO, PM, and many more. The majority of pollutants are released via exhaust systems and about 45% of HC and a small amount of others are ejected by the vehicle's crank case and fuel oil system.

Among those materials mentioned, CO is the product of incomplete combustion and does great harm to humans and the environment around us. HC contains cancer-causing substances and is produced because of fuel evaporation and incomplete combustion. After being released to the air, HC will react with NOX and create NO2, which is poisonous and has a bad effect on the growth of human and plants. Besides, NO2 is also one of the elements of acid rain and photochemical smog. As for PM, it refers to particulate matters that will stay in lungs for a long time after inhalation.

In order to reduce the release of these materials and provide human beings safe and clean air, three-way catalyst converter is thus invented. It's composed of palladium, platinum and rhodium, and removes 90% of the pollutants in the air. When going through three-way catalyst, the activity of gases is improved under high temperature. CO is converted into CO2, HC is turned into water and CO2 and NOX is reduced into N2.

Hualian successfully developed many types of three-way catalyst suitable for vehicles on the market. With the application of our catalyst converters and supports, the auto emission complies with national standard. What's more, we also provide customization service depending on customer's specific demands.

Features of Three-way Catalyst Support

1. Raw Material

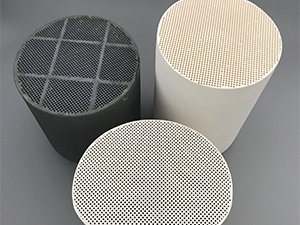

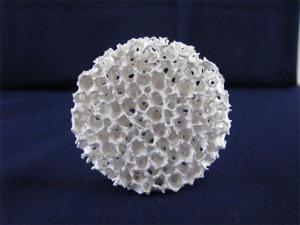

Main materials of catalyst carrier include MgO2, Al2O3 and SiO2, in order to offer an inert environment. To get a relative larger reaction surface within a limited volume, catalyst support usually has a honeycomb structure.

2. Coating

The three-way catalyst is covered with an active layer (γ-AL2O3). Due to the honeycomb structure, the reaction surface is increased by 7000 times, thereby enlarging the active area and enhancing oxygen storage capacity. In addition, on the active layer is coated with promoter containing Zr and Ce.

Matters Need Attention

(1) Keep the engineer in a good condition to get an ideal air-fuel ratio and security combustion.

(2) Avoid sudden start-up.

(3) Optimal working temperature: 400 ℃-800℃, maximum working temperature: 1000℃. Otherwise, the catalyst will be aging quickly and have a shorter lifespan.

(4) Leakage of engine oil will reduce the activity of catalyst.

You may also find products like:

Ceramic Catalyst, Ceramic Substrate, Catalytic Converter