About Hualian

Hualian has been manufacturing honeycomb ceramics and catalysts for more than 30 years and we have continuously expanded our product catalog beyond honeycomb ceramics to catalysts, ceramic balls, adsorbents, catalyst support media, and tower packing. Today, honeycomb ceramic products are used in petroleum, chemical, pharmaceutical, pesticide, mining, smelting, food, and even sewage treatment applications. Details

Main Products

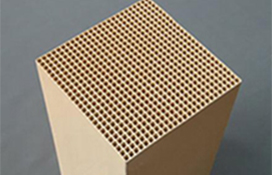

- Thermal Storage Honeycomb Ceramic High temperature air combustion or HTAC is a technology that was developed for energy efficiency and environmental protection. When compared to traditional combustion methods, HTAC systems can reduce fuel consumption by 20-50% and lowers oxidation burn loss by 20% as well as NOx exhaust by more than 40%.

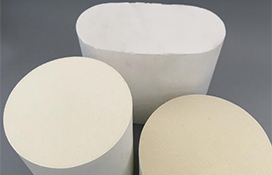

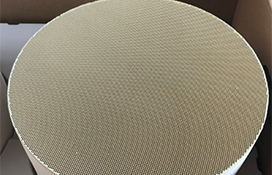

- Three-Way Catalyst Support The Hualian three-way catalyst is designed for a wide range of engines and meets all relevant emission standards. In addition to high quality products, we also provide customization services to meet the most specific customer requests.

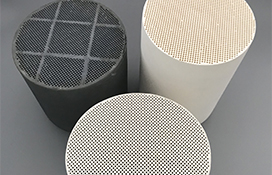

- Diesel Particulate Filter This DPF emission solution filters at least 80% of carbon substances from exhaust systems. It does a fantastic job relieving air pollution from combustion engines.

- Selective Catalytic Reduction Catalyst, SCR Catalyst The catalyst support is made from cordierite and is most often applied in the catalytic converter of diesel emission purification systems. After the catalytic conversion and purification, exhaust gases are then compliant with European IV and European V standards.

- Ammonia Decomposition Catalyst The ammonia decomposition catalyst is mainly used in ammonia decomposition furnaces of coal gas purification and recovery systems. It turns toxic gases into N2, H2 and CO2 effectively removing the threat of equipment corrosion in coal gas recover furnaces. It also prevents pollutants from entering the atmosphere.

- Hydrogenation Catalyst The hydrogenation catalyst is mainly used in the hydrogenation of unsaturated aliphatic hydrocarbon as well as aromatic hydrocarbon, and organic sulfides removal from liquid alkane. After using the catalyst, the content of remaining aromatic hydrocarbons or unsaturated hydrocarbons can be decreased to ppm grade. The sulfide content in liquid hydrocarbons can be decreased to less than 0.1ppm.

- Sulfur Recovery Catalyst In order to protect the environment and recover sulfur before it can be released into the air, the sulfur recovery catalyst handles acidic gases released during operation.

- Zinc Oxide Desulfurization Catalyst The zinc oxide desulfurization catalyst features excellent hydrogen sulfide removal performance and has a transfer capacity for organic sulfur compounds. Under normal temperatures, the sulfur removal catalyst maintains its high desulfurization activity and boasts a removal rate up to 99.5%. This is extremely important in synthesis ammonia factories that make use of semi-aqueous gasses as raw materials.