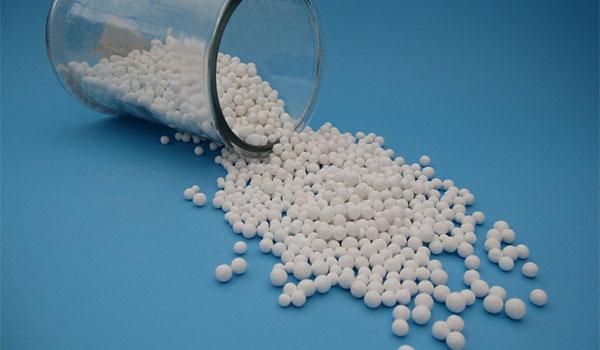

3A molecular sieve is mainly used for adsorbing water and cannot remove molecules with a diameter bigger than 3A. The molecular sieve adsorbent is known for fast adsorption speed, recycle usage, high crushing strength, anti-contamination, long service life and high efficiency. A wide application of the molecular sieve is found in petroleum industry and chemical industry for deep drying, refining and polymerizing gases and liquids.

Technical Parameters of 3A Molecular Sieve| Model | 3A | |||

| Color | Beige | |||

| Pore size | 3A | |||

| Shape | Ball | Bar | ||

| Size (mm) | 1.7-2.5 | 3.0-5.0 | 1.6 | 3.2 |

| Size qualification (%) | ≥98 | ≥98 | ≥96 | ≥96 |

| Bulk density (g/ml) | ≥0.72 | ≥0.70 | ≥0.66 | ≥0.66 |

| Attrition loss (%) | ≤0.20 | ≤0.20 | ≤0.20 | ≤0.20 |

| Crushing strength (N) | ≥55/particle | ≥85/particle | ≥30/particle | ≥40/particle |

| Water adsorption (%) | ≥21.0 | ≥21.0 | ≥21.0 | ≥21.0 |

| Ethylene adsorption ( ‰) | ≤3.0 | ≤3.0 | ≤3.0 | ≤3.0 |

| Water in packaging (%) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

| Composition | 0.4K2O. 0.6Na2O. Al2O3. 2SiO2. 4.5H2O SiO2: Al2O3≈2 | |||

| Applications | (1) Liquids, like ethyl alcohol | |||

| (2) Air | ||||

| (3) Natural gas, methane gas | ||||

| (4) Unsaturated hydrocarbon, pyrolysis gas, ethylene, acetylene, propylene, butadiene | ||||

4A molecular sieve provides better water adsorption capacity than other types of industrial adsorbents and is one of the most widely used molecular sieves in industry. Typical adsorbed materials include water, methanol, ethanol, hydrogen sulfide, sulfur dioxide, carbon dioxide, ethylene and propylene. It cannot remove any molecules that the diameter is bigger than 4A.

Technical Parameters of 4A Molecular Sieve| Model | 4A | |||

| Color | Beige | |||

| Pore size | 4A | |||

| Shape | Ball | Bar | ||

| Size (mm) | 1.7-2.5 | 3.0-5.0 | 1.6 | 3.2 |

| Size qualification (%) | ≥98 | ≥98 | ≥96 | ≥96 |

| Bulk density (g/ml) | ≥0.72 | ≥0.70 | ≥0.66 | ≥0.66 |

| Attrition loss (%) | ≤0.20 | ≤0.20 | ≤0.20 | ≤0.20 |

| Crushing strength (N) | ≥35/particle | ≥85/particle | ≥35/particle | ≥70/particle |

| Methanol adsorption (%) | ≥15.0 | ≥15.0 | ≥15.0 | ≥15.0 |

| Water adsorption (%) | ≥22.0 | ≥22.0 | ≥22.0 | ≥22.0 |

| Water in packaging (%) | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 |

| Composition | Na2O.Al2O3 .2SiO2.4.5H2O SiO2 : Al2O3≈2 | |||

| Applications | (1) Deep drying of gases and liquids, like air, natural gas, alkane, refrigerating fluid. | |||

| (2) Manufacture and purification of argon | ||||

| (3) Static drying of medicine packaging, electronic elements and perishable materials. | ||||

| (4) Dehydration of oil paints, fuels and coatings. | ||||

5A molecular sieve adsorbs molecule whose diameter is smaller than 5A and is mainly applied for the pressure swing adsorption and separation of hydrocarbon as well as co-adsorption of water and carbon dioxide. 5A mole sieve is characterized by high adsorption and fast adsorbing speed, extremely suitable for pressure swing adsorption of oxygen, hydrogen and carbon dioxide.

Technical Parameters of 5A Molecular Sieve13X molecular sieve has a pore size of 10A and is suitable for drying catalyst supports and co-adsorbing water and carbon dioxide, water and sulfuretted hydrogen. An application is found in the drying system of medicine and air. According to the application environment, we provide different molecular sieves.

Technical Parameters of 13X Molecular Sieve| Model | 13X | |||

| Color | Beige | |||

| Pore size | 10A | |||

| Shape | Ball | Bar | ||

| Size (mm) | 1.7-2.5 | 3.0-5.0 | 1.6 | 3.2 |

| Size qualification (%) | ≥98 | ≥98 | ≥96 | ≥96 |

| Bulk density (g/ml) | ≥0.70 | ≥0.68 | ≥0.65 | ≥0.65 |

| Attrition loss (%) | ≤0.20 | ≤0.20 | ≤0.20 | ≤0.20 |

| CO2 adsorption (%) | ≥17.0 | ≥17.0 | ≥17.0 | ≥17.0 |

| Crushing strength (N) | ≥35/particle | ≥85/particle | ≥30/particle | ≥45/particle |

| Water adsorption (%) | ≥25 | ≥25 | ≥25 | ≥25 |

| Water in packaging (%) | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 |

| Composition | Na2O.Al2O3.2.45SiO2.6H2O SiO2 : Al2O3≈2 | |||

| Applications | (1) Deep drying of industrial gases | |||

| (2) Feed gas purification. (Eliminate H2O, CO2 and hydrocarbon) | ||||

| (3) Oxygen production | ||||

| (4) Drying and desulfurization of natural gas, liquefied petroleum gas, liquid hydrocarbon | ||||

Developed for cryogenic air separation, 13X APG molecular sieve possesses improved removal capacity of carbon dioxide and water and well avoids frozen tower problem of reaction tower.

Technical Parameters of 13X APG Molecular Sieve| Model | 13X APG | |||

| Color | Yellow | |||

| Pore size | 10A | |||

| Shape | Ball | Bar | ||

| Size (mm) | 1.7-2.5 | 3.0-5.0 | 1.6 | 3.2 |

| Size qualification (%) | ≥98 | ≥98 | ≥96 | ≥96 |

| Bulk density (g/ml) | ≥0.70 | ≥0.68 | ≥0.65 | ≥0.65 |

| CO2 adsorption (%) | ≥18 | ≥18 | ≥18 | ≥18 |

| Attrition loss (%) | ≤0.20 | ≤0.20 | ≤0.20 | ≤0.20 |

| Crushing strength (N) | ≥35/particle | ≥85/particle | ≥30/particle | ≥45/particle |

| Water adsorption (%) | ≥27.0 | ≥27.0 | ≥27.0 | ≥27.0 |

| Water in packaging (%) | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 |

| Composition | Na2O. Al2O3. 2.45SiO2.6H2O SiO2 : Al2O3 ≈2 | |||

| Application | (1) Remove water and carbon dioxide from air to make nitrogen | |||

You may also find products like:

Moleuclar Sieve, Ddsorbent, Dryer