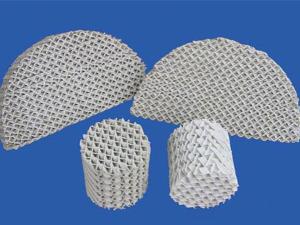

Metal random packing is made using carbon steel, stainless steel and other metals as raw material. Metal random tower packing offered by Hualian is characterized by thin thickness, thermal resistance, high porosity, large flux, small resistance and high separation efficiency.

Metal random packing is an ideal choice for the vacuum distillation of materials which are thermal sensitive and easy to decompose, polymerize and carbonize. A wide application of metal random packing is found in industries as petrochemical engineering, chemical fertilizer and environmental protection.

Technical Parameters of Pall Ring

| Spec. |

Size |

Bulk density, kg/m2 |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Porosity, % |

| 10 |

φ 10 × H 10 × 0.3 |

571 |

768000 |

482 |

92.7 |

| 16 |

φ 16 × H 16 × 0.3 |

408 |

214000 |

362 |

94.9 |

| 25 |

φ 25 × H 25 × 0.5 (0.4) |

403 (322) |

51940 |

219 |

95 |

| 38 |

φ 38 × H 38 × 0.6 (0.4) |

326 (217) |

15180 |

146 |

95.9 |

| 50 |

φ 50 × H50 × 0.8 (0.5) |

322 (201) |

6500 |

109 |

96 |

| 76 |

φ 76 × H76 × 1.0 (0.6) |

262 (157) |

1830 |

71 |

96.1 |

| 89 |

φ 89 × H89 × 1.2 (0.7) |

283 (165) |

1200 |

65 |

98 |

Technical Parameters of Hypak Ring

| Diameter, mm |

Bulk number, pcs/m3 |

Bulk Density (kg/m3) |

Porosity, % |

Dry packing factor, m-1 |

| 76 |

1100 |

208 |

97.7 |

49 |

| 50 |

3670 |

224 |

97.4 |

59 |

| 38 |

9390 |

280 |

97 |

85 |

| 25 |

29900 |

312 |

96.5 |

141 |

Technical Parameters of Raschig Ring

| Spec. |

Diameter, mm |

Bulk Density (kg/m3) |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Porosity, % |

| 10 |

φ 10 × H10 × 0.3 |

571 |

768000 |

500 |

75 |

| 12.7 |

φ 12.7 × H12.7 × 0.3 |

490 |

410000 |

400 |

80 |

| 16 |

φ 16 × H16 × 0.3 |

408 |

214000 |

350 |

86 |

| 25 |

φ 25 × H25 × 0.5 (0.4) |

403 (322) |

51940 |

220 |

88 |

| 38 |

φ 38 × H38 × 0.6 (0.4) |

326 (217) |

15180 |

150 |

90 |

| 50 |

φ 50 × H50 × 0.8 (0.5) |

322 (201) |

6500 |

110 |

82 |

| 76 |

φ 76 × H76 × 1.0 (0.6) |

262 (157) |

1830 |

68 |

95 |

| 89 |

φ 89 × H89 × 1.2 (0.7) |

283 (165) |

1200 |

58 |

97 |

Notes:

1. The thickness can be designed upon request.

2. Above parameters are only for reference.

Technical Parameters of Nutter Ring

| No. |

Bulk number, pcs/m3 |

Bulk Density (kg/m3) |

Specific surface area, m2/m3 |

Porosity, % |

| NO.0.7 |

167400 |

176 |

266 |

97.7 |

| NO.1.0 |

67100 |

178 |

168 |

97.7 |

| NO.1.5 |

26800 |

181 |

124 |

97.8 |

| NO.2.0 |

13600 |

173 |

96 |

97.8 |

| NO.2.5 |

8800 |

83 |

83 |

97.9 |

| NO.3.0 |

4200 |

66 |

66 |

98.1 |

Notes:

1. The thickness can be designed upon request.

2. Above parameters are only for reference.

Technical Parameters of IMTP Ring

| Model |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Porosity, % |

Dry packing factor, m-1 |

| #15 |

347500 |

291.3 |

95.6 |

51 |

| #25 |

135000 |

225.8 |

96.6 |

41 |

| #40 |

50000 |

150.8 |

97.7 |

28 |

| #50 |

15000 |

100 |

98 |

18 |

| #70 |

4625 |

60 |

98.5 |

12 |

Technical Parameters of Industry-Standard IMTP Ring

| Model |

OD× height× thickness, mm |

Bulk number, pcs/m3 |

Bulk Density (kg/m3) |

Specific surface area, m2/m3 |

Porosity, % |

Dry packing factor, m-1 |

| Dg16 |

15 × 9 × 0.3 |

347500 |

240 |

291.3 |

95.6 |

253 |

| Dg25 |

25 × 15 × 0.3 |

57720 |

161 |

171 |

97.6 |

184 |

| Dg38 |

38 × 16.5 × 0.4 |

38160 |

155 |

123 |

97.7 |

132 |

| Dg50 |

50 × 29 × 0.5 |

11310 |

129 |

79 |

98.2 |

83 |

| Dg76 |

70 × 35.5 × 0.6 |

4250 |

112 |

55 |

98.5 |

58 |

Technical Parameters of Cascade Ring

| Spec. |

Size, mm (OD × ID) |

Bulk density, kg/m3 |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Porosity, % |

Dry packing factor, m-1 |

| 0P |

φ 17 ×φ 15 × H6 × 0.3 |

472 |

530000 |

427 |

94 |

55 |

| 1P |

φ 25 ×φ 22 × H8 × 0.3 |

270 |

150000 |

230 |

96 |

40 |

| 1.5P |

φ 34 ×φ 29 × H11 × 0.3 |

201 |

60910 |

198 |

97 |

29 |

| 2P |

φ 43 ×φ 38 × H14 × 0.4 |

230 |

33170 |

164 |

97 |

22 |

| 2.5P |

φ 51 ×φ 44 × H17 × 0.4 |

186 |

17900 |

127 |

97 |

17 |

| 3P |

φ 66 ×φ 57 × H21 × 0.4 |

139 |

8800 |

105 |

98 |

14 |

| 4P |

φ 86 ×φ 76 × H29 × 0.4 |

143 |

5000 |

90 |

98 |

10 |

| 5P |

φ 131 ×φ 118 × H41 × 0.6 |

136 |

1480 |

65 |

98 |

7 |

Technical Parameters of Industry-Standard Cascade Ring

| Model |

Diameter× height× thickness, mm |

Bulk number, pcs/m3 |

Bulk Density (kg/m3) |

Specific surface area, m2/m3 |

Porosity, % |

Dry packing factor, m-1 |

| DN76 |

76 × 38 × 1.2 |

3540 |

385 |

72 |

0.961 |

81 |

| DN50 |

50 × 25 × 0.8 |

12340 |

385 |

109 |

0.961 |

123 |

| DN38 |

38 × 19 × 0.6 |

30040 |

433 |

153 |

0.959 |

173 |

| DN25 |

25 × 12.5 × 0.5 |

98120 |

459 |

221 |

0.951 |

257 |

Notes:

1. The density is of carbon steel and stainless steel.

2. Thickness: Copper: 1.14 mm, aluminum: 0.34 mm, monel: 1.14 mm. The thickness can be customized.

3. Above parameters are only for reference.

Technical Parameters of Metal Mellaring Ring

| Diameter, mm |

Size (mm) |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Porosity, % |

| 76 |

63 × 63 |

3000 |

72 |

0.98 |

| 50 |

50 × 50 |

7000 |

90 |

0.98 |

| 38 |

38 × 38 |

14500 |

110 |

0.98 |

| 25 |

25 × 25 |

33500 |

205 |

0.975 |

Technical Parameters of Metal Conjugate Ring

| Model |

Size, mm |

Specific surface area, m2/m3 |

Porosity, % |

Bulk Density (kg/m3) |

Bulk number, pcs/m3 |

Dry packing factor |

| φ 16 |

16 × 0.4 |

313 |

0.97 |

354 |

211250 |

340 |

| φ 25 |

25 × 0.6 |

185 |

0.95 |

216 |

75000 |

312 |

| φ 38 |

38 × 0.8 |

116 |

0.96 |

131 |

19500 |

296 |

| φ 50 |

50 × 0.8 |

86 |

0.96 |

97 |

9772 |

268 |

| φ 76 |

76 × 0.8 |

81 |

0.95 |

94.5 |

3980 |

247 |

Technical Parameters of QH-1 Mini Ring

| Material |

Type |

Size (mm) |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Porosity, % |

Bulk Density (kg/m3) |

Note |

| Metal |

16 |

16 × 5.5 × 0.6 |

378000 |

348 |

0.923 |

492 |

Carbon steel, stainless steel, copper, aluminum, monel alloy, nickel and titanium are available. The material can also be chosen upon request. |

| 25 |

25 × 9.0 × 0.6 |

155000 |

228 |

0.936 |

516 |

| 38 |

38 × 12.7 × 0.8 |

48000 |

150 |

0.95 |

400 |

| 50 |

50 × 17.0 × 0.8 |

21500 |

120 |

0.965 |

360 |

| Plastic |

50 |

50 × 17 × 1.5 |

21500 |

120 |

0.965 |

81.7 |

PP, reinforced PP, PVC, COVC |

| 75 |

75 × 25 × 2.5 |

7000 |

89 |

0.975 |

70 |

Technical Parameters of QH-2 Mini Ring

| Material |

Type |

Size (mm) |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Porosity, % |

Bulk Density (kg/m3) |

Note |

| Metal |

16 |

16 × 5.5 × 0.3 |

406000 |

312 |

95.7 |

339 |

Carbon steel, stainless steel, copper, aluminum, monel alloy, nickel and titanium are available. The material can also be chosen upon request. |

| 25 |

25 × 9.0 × 0.4 |

166000 |

256 |

95.4 |

351 |

| 38 |

38 × 12.7 × 0.6 |

52000 |

170 |

95.2 |

344 |

| 50 |

50 × 17.0 × 0.8 |

23000 |

125 |

95.6 |

389 |

Technical Parameters of QH-3 Mini Ring

| Type |

Dimensions (mm) |

Bulk number, pcs/m3 |

Specific surface area, m2/m3 |

Void volume (m3/m3) |

Bulk density (kg/m3) |

Note |

| 16 |

16 ×5.5 ×0.3 |

378000 |

348 |

0.934 |

246 |

Manufacture can be customized upon request |

| 25 |

25 ×9.0 ×0.4 |

155000 |

228 |

0.955 |

344 |

| 38 |

38 ×12.7 ×0.6 |

48000 |

150 |

0.963 |

342 |

| 50 |

50 ×17.0 ×0.8 |

21500 |

120 |

0.972 |

315 |

| 75 |

75 ×25 ×0.9 |

5800 |

70 |

0.985 |

243 |

You may also find products like:

Metal Random Tower Packing, Pall Ring Packing, Metal Nutter Ring Packing